Maximizing Efficiency with Pig System ROI

In industries that rely on pipelines for the transportation of products, maintaining operational efficiency is crucial. A pigging system is a vital tool used to clean, inspect, and maintain pipelines, enhancing their performance and reliability. By investing in pigging technology, businesses can unlock a significant return on investment (ROI). This article explores the relationship between pigging systems and ROI, showcasing how these systems contribute to long-term profitability through improved efficiency, reduced downtime, and minimized maintenance costs.

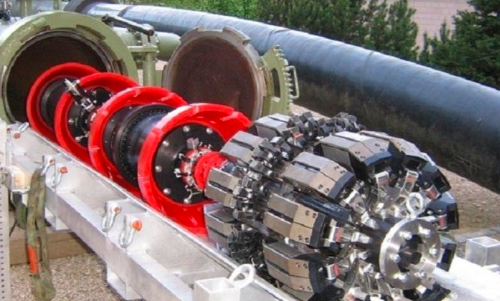

Understanding the Pig System

A pigging system is a pipeline maintenance solution that utilizes “pigs”—devices inserted into pipelines to perform various tasks such as cleaning, product separation, and inspection. These systems help ensure that pipelines function at peak performance levels pig system roiby removing contaminants, debris, and other obstructions that may hinder the flow of products.

Pigging systems offer a range of benefits, including increased pipeline longevity, minimized risk of contamination, and reduced operational downtime. In addition to these advantages, the ROI associated with implementing a pigging system is undeniable.

How Pigging Systems Deliver ROI

The investment in a pigging system might require initial capital outlay, but the long-term benefits more than make up for this expense. Below are several ways in which pigging systems contribute to significant ROI:

1. Improved Pipeline Efficiency

The most direct way in which pigging systems enhance ROI is by improving pipeline efficiency. A clean pipeline facilitates smooth product flow, reducing friction and preventing the buildup of debris or sludge that can impede the flow of materials. For industries such as oil and gas, food processing, and pharmaceuticals, ensuring that pipelines are free from contaminants can help reduce energy consumption and keep operations running at full capacity.

The improved flow efficiency also helps businesses reduce energy costs. For example, in oil pipelines, the pumping energy required to move fluids through a clean, unobstructed pipeline is significantly lower compared to a pipeline clogged with debris. This reduction in energy consumption leads to substantial savings in utility costs over time.

2. Reduction in Downtime

Unplanned pipeline shutdowns due to blockages or contamination can cause significant downtime, which leads to lost productivity and higher operational costs. Pigging systems help to prevent such disruptions by ensuring pipelines remain free from buildup. As a result, businesses can avoid costly downtime, keep production on track, and improve overall productivity.

Unlike traditional cleaning methods, which often require a full shutdown of the pipeline, pigging systems are designed to operate in-line, meaning that maintenance can be conducted without interrupting the flow of goods. This capability greatly minimizes downtime, allowing for continuous operations and more efficient use of resources.

Read also: Keys to Preparing Your Business for Emergencies

3. Cost Savings on Maintenance

Regular cleaning and inspection are necessary to maintain pipelines in optimal condition. However, traditional pipeline maintenance methods often require manual labor, equipment downtime, and costly repairs. Pigging systems, on the other hand, automate much of the cleaning and inspection process, reducing the need for manual intervention and cutting down on labor costs.

Moreover, because pigging systems help prevent the accumulation of debris, corrosion, or other materials that can lead to more severe pipeline damage, businesses can reduce the need for expensive repairs. This proactive approach to maintenance reduces the likelihood of unanticipated breakdowns and extends the life of the pipeline, further increasing the overall ROI.

4. Prevention of Contamination

In industries that prioritize product quality and safety—such as food and beverage, pharmaceuticals, and chemicals—ensuring that the pipeline is free of contaminants is essential. Pigging systems play a vital role in preventing contamination by cleaning the interior of pipelines and separating different products being transported through the same pipeline.

For instance, in the pharmaceutical industry, contamination of products can lead to severe regulatory fines, product recalls, and damage to a company’s reputation. Pigging systems help ensure that each product batch remains uncontaminated, which not only maintains high-quality standards but also reduces the risk of legal and financial repercussions.

In food production, preventing contamination ensures consumer safety and compliance with health regulations. Therefore, using pigging systems to safeguard against contamination protects a company’s profitability by reducing the potential for costly recalls or lawsuits.

5. Longer Pipeline Lifespan

A significant benefit of pigging systems is their ability to extend the lifespan of pipelines. Over time, the buildup of residues, corrosion, and other obstructions can weaken the structural integrity of a pipeline. Regular use of pigging systems ensures that these issues are identified and addressed before they cause permanent damage.

By using pigging systems to regularly clean and inspect pipelines, businesses can avoid costly repairs and replacements. This reduces capital expenditure on new pipeline infrastructure and improves the ROI of existing assets. With a well-maintained pipeline, businesses can continue operations without worrying about the high costs associated with pipeline failure.

6. Improved Regulatory Compliance

Adherence to industry regulations is crucial for businesses in sectors like pharmaceuticals, chemicals, and food production. Failure to comply with regulatory standards can result in fines, legal action, and a damaged brand reputation. Pigging systems support regulatory compliance by ensuring that pipelines are maintained in a clean and safe condition.

For example, in the food industry, pigging systems ensure that different products are not mixed and that the pipes are free from contaminants. Similarly, in the pharmaceutical industry, regular cleaning and inspection of pipelines prevent cross-contamination and ensure that products are safe for consumers. By maintaining compliance with regulatory standards, businesses avoid costly legal penalties and protect their market standing, all of which contributes to a higher ROI.

Conclusion

Implementing a pigging system offers a range of advantages that contribute directly to improved ROI. From enhancing pipeline efficiency and reducing downtime to preventing contamination and extending the lifespan of pipelines, pigging systems provide substantial value to businesses across various industries.

By automating pipeline maintenance, reducing costs, and ensuring product quality, businesses can reap the long-term benefits of pigging systems. In industries where pipeline infrastructure plays a crucial role in operations, the ROI from a pigging system can significantly impact profitability and overall business success. For companies seeking to optimize their operations and enhance their bottom line, investing in a pigging system is a strategic move that pays off in numerous ways.